What is Radiant Barrier?

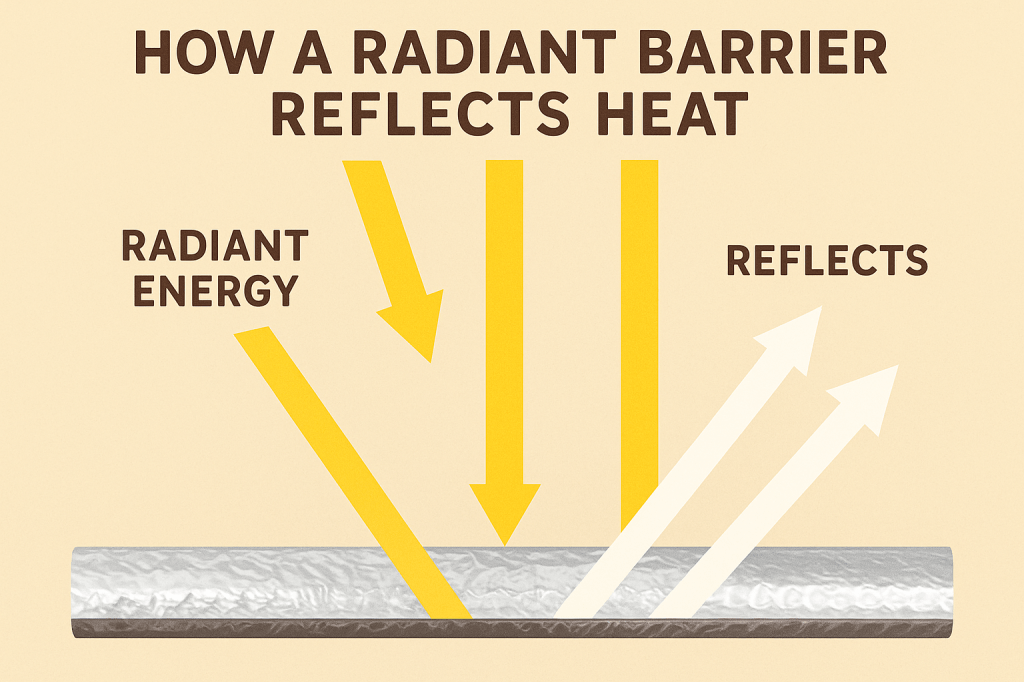

A radiant barrier is a highly reflective material—usually aluminum foil—used in building construction to reduce heat transfer and improve energy efficiency. It works by reflecting radiant energy instead of absorbing it, unlike traditional insulation.

In homes, they are commonly installed under roof decking, laid over attic floor insulation, or stapled to rafters to reduce summer heat gain. In commercial and industrial buildings, radiant barriers are often used in warehouses, metal buildings, and distribution centers where roof and wall surfaces are directly exposed to intense solar radiation. They’re also effective in retrofit projects, HVAC duct insulation, and under radiant floor systems. Because they function by reflecting radiant energy regardless of orientation, radiant barriers can be integrated into nearly any building envelope design to improve thermal performance and reduce cooling loads.

How Reflective Insulation Works

To fully appreciate the benefits of reflective insulation, it’s important to understand the science behind it. Below is a breakdown of the core principles that enable reflective insulation to deliver exceptional thermal performance.

Radiant Heat Reflection

At the heart of reflective insulation is its ability to reflect radiant heat. Unlike conventional insulation, which primarily slows conductive and convective heat transfer, reflective insulation targets radiant energy—responsible for the majority of heat gain in structures. Depending on the material and construction, reflective insulation can reflect between 94% and 97% of radiant heat back toward its source, significantly reducing unwanted heat transfer.

Thermal Performance Metrics

Reflective insulation’s effectiveness is largely measured by two properties: emissivity and reflectivity. Emissivity indicates how much heat a surface emits, while reflectivity measures how much is bounced back. Materials like aluminum foil or metallized films have very low emissivity values (typically 0.03–0.06), allowing them to reflect the majority of heat—between 94% and 97%. This high reflectivity helps maintain cooler interior temperatures in the summer and retain warmth in the winter, showcasing the superior thermal control of low-emittance materials.

Structure and Composition

Modern reflective insulation products are engineered with multiple layers to boost both durability and thermal performance. These layers commonly include reflective aluminum foil or metallized film combined with other materials such as polyethylene bubbles, foam, or scrim.

This layered construction not only enhances insulation performance but also adds strength and resistance to physical wear, making it ideal for long-term applications in residential, commercial, and industrial settings.

Why should I use radiant barrier?

You should use radiant barrier in your building or attic because it significantly reduces radiant heat transfer, which helps lower energy costs and improves indoor comfort — especially in hot climates. Here’s why it’s worth installing:

Top Benefits of Radiant Barrier

- Lowers attic temperatures by 20–40°F

Reduces the workload on your HVAC system and helps it run more efficiently. - Cuts cooling costs by up to 10–15%

Especially effective in southern and sunbelt states where summer heat is intense. - Improves comfort in upstairs rooms or bonus rooms over garages

These areas are usually the hottest in a home — radiant barrier helps even things out. - Enhances the performance of existing insulation

When radiant barrier reduces attic heat, your fiberglass or cellulose insulation performs better. - Affordable upgrade with long-term savings

Compared to other energy efficiency solutions, radiant barrier has a low install cost and high ROI.

For more technical information about how radiant barriers work see our Technical Information page.

Where is Reflective Insulation used.

1. Construction & Building Industry

This is the primary industry for radiant barrier use.

- Residential Homes – Used in attics, walls, roofs, and under flooring to reduce heat gain/loss.

- Commercial Buildings – Installed in warehouses, offices, and retail buildings to improve HVAC efficiency.

- New Construction – Incorporated in energy-efficient home and building designs.

- Remodeling/Renovation – Retrofitted into existing attics or walls to upgrade energy performance.

2. Industrial & Manufacturing

Facilities that generate or store heat-sensitive materials benefit from radiant barrier.

- Factories – Reduces internal temperatures in large metal structures.

- Storage Warehouses – Helps protect temperature-sensitive goods and reduces cooling costs.

- Clean Rooms – Helps regulate strict temperature and insulation standards.

3. Transportation & Logistics

Used to protect cargo from heat damage.

- Refrigerated Trucks & Trailers – Keeps internal temperatures lower and reduces cooling energy use.

- Shipping Containers – Lines the interior to protect from radiant heat during long hauls.

- Aircraft & Aerospace – Utilized in specialized thermal applications to reflect radiant energy.

4. Agriculture

Helps protect crops, livestock, and equipment from excess heat.

- Barns & Poultry Houses – Keeps animals cooler and reduces heat stress.

- Greenhouses – Reflective films are used to manage radiant heat and prevent overheating.

- Equipment Storage Sheds – Keeps machinery cooler and reduces wear from thermal expansion.

5. Energy Efficiency & Sustainability

Often specified in LEED-certified or green building projects.

- Energy Retrofit Companies – Offer radiant barrier as part of whole-home energy upgrades.

- Solar Installers – May recommend radiant barrier to improve building efficiency before or during PV installs.

- Weatherization Programs – Government and utility programs sometimes subsidize radiant barrier installs.

6. Medical & Specialty Applications

Used in controlled environments or temperature-sensitive areas.

- Medical Transport Containers – Maintains stable temperatures for vaccines or pharmaceuticals.

- Hospitals or Labs – In high-performance buildings where thermal control is critical.

See our General Installation Tips for more help on your next project.