Under a Floor:

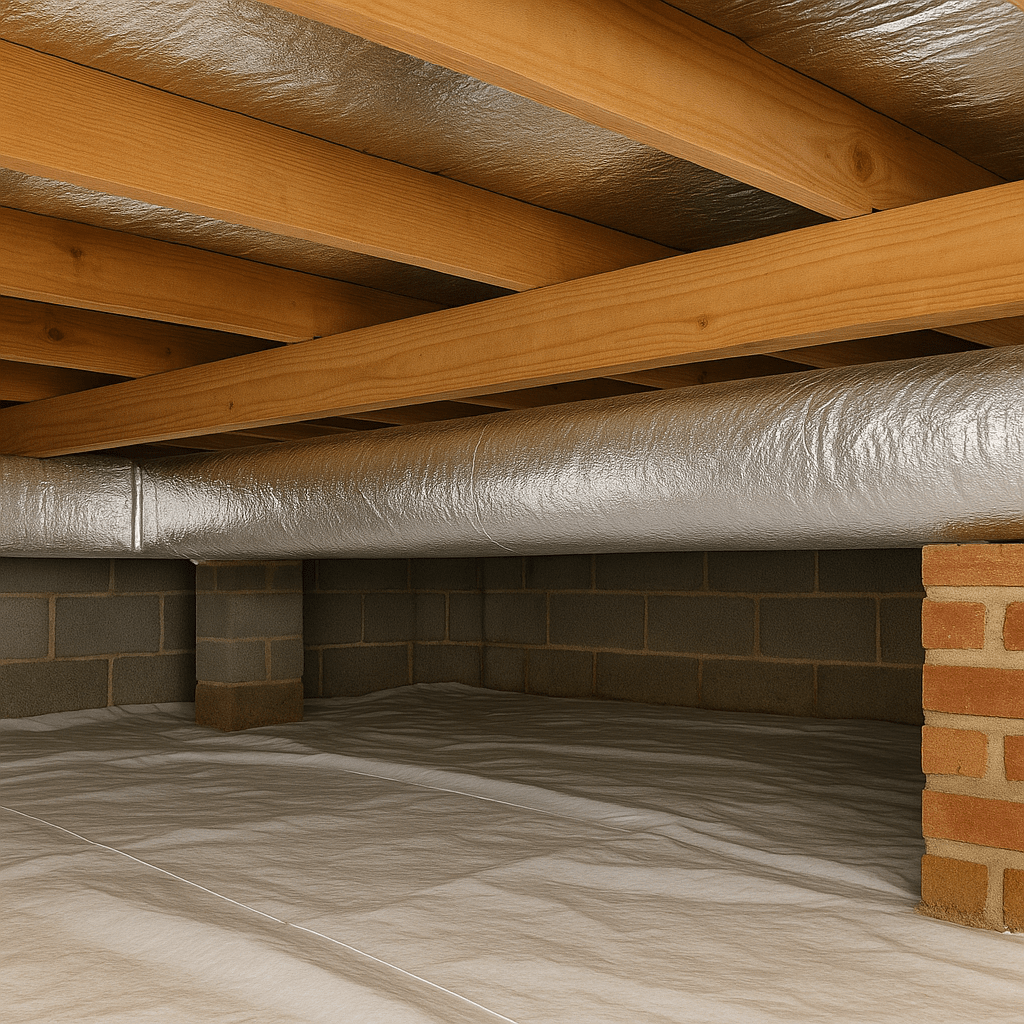

Radiant Barrier can be used under an elevated framed floor to cut down on heat gain or loss through flooring. The image below shows the radiant barrier reflecting install in the crawl space of a pier and beam house. Learn how to install a radiant barrier in the floor:

- For this application, you should use Silverback™ Perforated Radiant Barrier material.

- From the crawl space, unroll the Radiant Barrier and staple to the bottom of the floor joists, overlapping each run of radiant barrier by about 2 inches. Space the staples around 12 – 18 inches apart.

- Use foil tape to tape the seams and cut down on air infiltration.

- Depending on your floor configuration, you may find different material widths easier to work with. Silverback™ radiant heating insulation is available in the following widths: 48″, 26″, 24″, 18″, 16″

Radiant Heat Flooring:

In-floor radiant heating systems are growing in popularity, but they often lose heat to the space below. Installing a radiant barrier beneath the PEX tubing helps reflect the majority of radiant heat back upward, significantly reducing energy loss. To maximize efficiency, follow these best practices for radiant heat flooring installation:

- 1. It is highly recommended you use Silverback™ perforated material for this application.

- 2. Cut the Silverback™ material in strips or choose a width to match your floor joist spacing

- 3. Position the material beneath the radiant heat tubing, ensuring at least a 1 inch clearance. Secure it with staples to the sides of the floor joists or permit the material to lay atop the floor insulation.

- 4. Place your conventional (fiberglass) insulation on the underside of the Silverback™ material.

- Notes: Widths for dimensional lumber – 26″ for use with 24″ o.c. or 18″ for use with 16″ o.c.

Widths for manufactured floor joists – 24″ for use with 24″ o.c. or 16″ for use with 16″ o.c.

Radiant Heat between Heated Floors:

When installed between heated floors, a radiant barrier helps channel heat upward into the intended zone, improving overall system efficiency.

- 1. Silverback™ perforated material is recommended for this application.

- 2. The Silverback™ material should be cut in strips or choose a width to match your floor joist spacing

- 3. Install the material under radiant heat tubing with a minimum 1 inch clearance. Staple to the sides of the floor joists.

- Notes: Conventional insulation is generally not used in this application, except when sound control is desired. For dimensional lumber, use 26″ wide material with 24″ on-center spacing, or 18″ wide material with 16″ on-center spacing. For manufactured floor joists, use 24″ wide material for 24″ o.c. spacing and 16″ wide material for 16″ o.c. spacing.

See our General Installation Tips for more help on your next project.